We can now offer all the advantages of 5 Axis CNC Machining for larger components where complexity and high precision are required.

We can now offer all the advantages of 5 Axis CNC Machining for larger components where complexity and high precision are required.

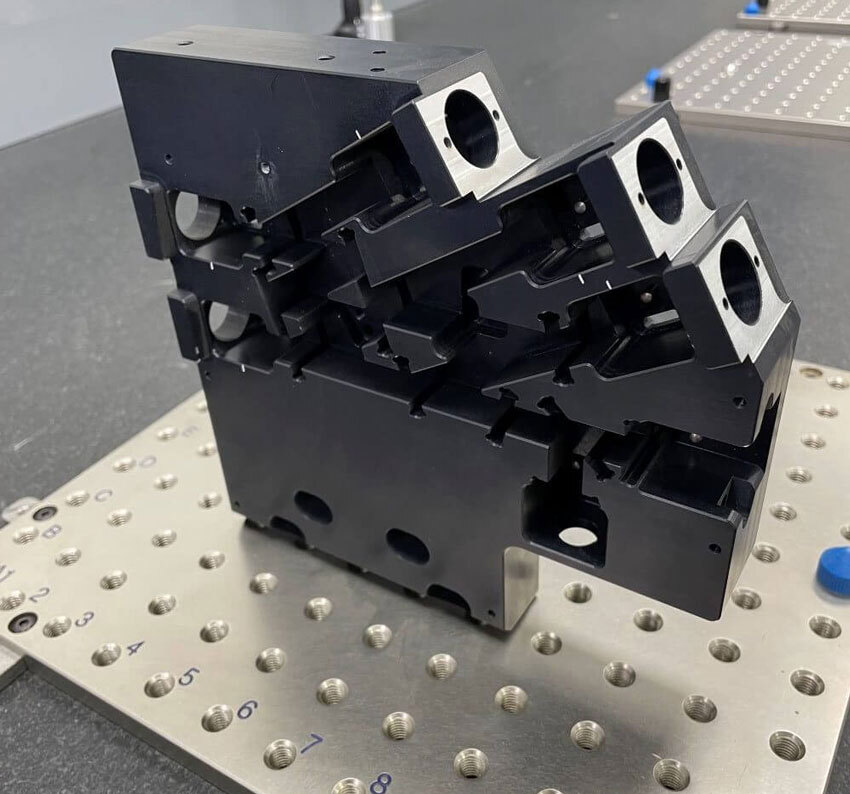

The process of producing intricate and accurate parts in low volume has been revolutionized by 5 Axis CNC Milling technology. By demanding a high level of accuracy, the performance of both large and small parts can be optimised. The use of 5 Axis Machining allows for components to be produced in just one setup, eliminating errors that can occur during multiple setups 3 Axis Machines..

5 Axis Milling at a large scale presents a viable alternative to the metal casting process, especially for complex shapes in low volume. Milling the part from solid material can often be more cost-effective than using expensive pattern equipment for casting. Additionally, 5 Axis Machining is considerably faster than traditional casting methods, with components being completed in just a few days compared to several weeks.

5 Axis Machining provides a much higher level of precision than casting and allows designers to minimise the weight of precision parts. For applications such as aerospace, military, and motorsport, the highest possible strength-to-weight ratio is often required. Milling parts from solid materials gives designers the assurance of using premium materials with minimal opportunity for material defects that can be present in cast materials.

Benefits of Large 5 Axis CNC Machining

Precision

5 Axis Machining provides a higher level of accuracy than other machining techniques. It allows our engineers to produce parts with tighter tolerances, resulting in a more precise and reliable finished product – crucial when making parts for Aerospace, Defence, or Scientific industries.

Efficiency

With 5 Axis Machining, our engineers can produce complex parts in just one setup, which eliminates the need for multiple setups on conventional machines. This saves time, reduces errors, and increases overall efficiency.

Flexibility

5 Axis Machining can handle a wide variety of part geometries and designs, which gives Design-Engineers greater design flexibility. Thompson Precision’s 5 Axis Machining capabilities enables us to create these more complex and intricate parts, which may prove difficult or impossible to make using other machining methods.

Why Thompson Precision Engineers?

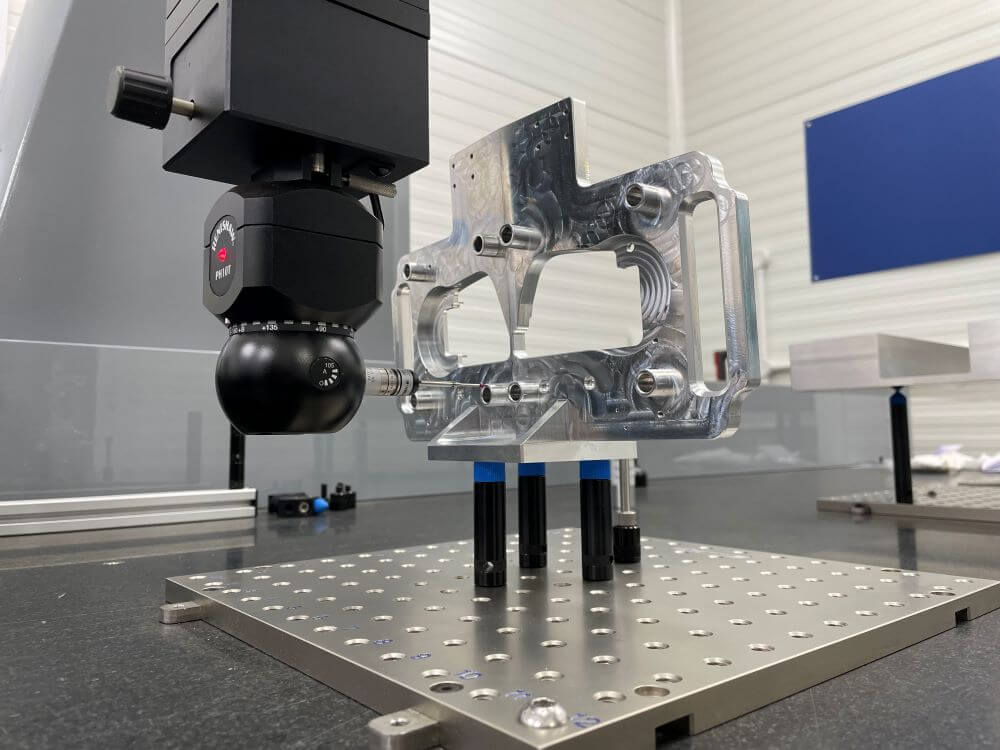

Combining our 5 Axis capabilities with our Mechanical Design Services, our expert engineers can help you determine which projects may benefit from 5 Axis CNC Machining and how parts may be redesigned for increased efficiency. We can also provide inspection reports for parts using our large CMM (Co-Ordinate Measuring Machine) to ensure all precision parts are machined accurately to the supplied CAD or drawings.

Combining our 5 Axis capabilities with our Mechanical Design Services, our expert engineers can help you determine which projects may benefit from 5 Axis CNC Machining and how parts may be redesigned for increased efficiency. We can also provide inspection reports for parts using our large CMM (Co-Ordinate Measuring Machine) to ensure all precision parts are machined accurately to the supplied CAD or drawings.

Overall, 5 axis CNC machining is a powerful tool that our engineers utilise to produce complex components faster, more accurately, and more efficiently than through other machining techniques. Get in touch with us to discuss your project and to see how we can help.