As technology advances, so does the capabilities of machines. This has led to new ways of thinking when it comes to machining processes. Two popular methods are laser cutting and CNC machining. We will take a look at how they compare and how each process is best suited for certain applications. So, whether you’re a manufacturer looking to update your process or simply curious about the latest and greatest in machine technology, read on!

CNC machines and laser cutting

Both are amazing tools that have revolutionised the way we make and create things. CNC machines are used in the manufacturing process in which control systems are used to automate a series of complicated mechanical operations, such as cutting and drilling. Laser cutting, on the other hand, uses powerful laser beams to cut through material.

Together, these two advanced technologies give us the ability to quickly and accurately create intricate components without relying on traditional methods like hand-crafting or manual machining. CNC machining provides extreme precision whereas laser cutting offers unmatched speed, making them ideal for creating complex parts with minimal effort. Whether you’re crafting an exact replica or producing a large batch of custom parts – CNC machining and laser cutting open up exciting new possibilities for creators everywhere!

Differences between the two processes

Working out the differences between two processes can be a challenging task, yet immensely rewarding. In most cases, the major difference lies in their approach: one process may take an incremental step-by-step approach, while the other might take a more holistic route and encapsulate the big picture of an activity all at once.

Another common distinction is based on how automated each process is; one may rely heavily on clever automation to get things done quickly, whereas the other may require more manual intervention and input from human operators.

As such, there are a variety of nuances that can help to identify and compare two processes, making it worth the time investment to probe and understand them both in great detail.

What is laser cutting?

Laser cutting is a sophisticated technology that uses a powerful laser beam to cut through or engrave a variety of materials. This unique technology can be used in many different applications and industries, such as manufacturing, jewellery making, or architectural design

At its core, laser cutting works by directing high-powered light towards a material and melting or vaporizing it based on the desired outcome. It offers great precision and accuracy due to the small size of the focused laser beam, which can easily make cuts or marks that are only fractions of an inch wide

What is a CNC machine used for?

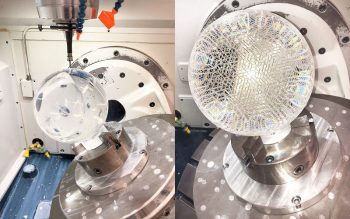

A CNC machine, or computer numerical control machine, is a type of advanced manufacturing tool that uses automated controls to precisely manipulate a variety of materials and components. Common uses for CNC machines include cutting, milling, drilling, and engraving tasks that are often too intricate or labour-intensive to be performed manually

CNC machines can be used in many different industries and applications, including automotive manufacturing, aerospace engineering, high-tech product design, electronics assembly, and more. With its ability to automate complex processes quickly and accurately, a CNC machine is truly an indispensable tool for modern manufacturers and engineers alike.

Why Work with Thompson Precision?

Not sure which technology to use?

Our team are supported by a fully equipped and highly skilled team whose experience of CNC machining and laser cutting is hands on and extensive.

The speed of the development, prototype and production process which is achievable with the current technology, equipment and processes allow us to provide a quick and highly accurate service.

Our team can advise on the material and process that is used within your project to get you the very best results. Our CNC knowledge and cutting and laser work spans across a large number of industries and so you can feel sure that you are in the very safest of hands.

To see some examples of our work, please take a look at our Gallery and our CNC services case studies.