Welcome to Thompson Precision – Your Expert Mechanical Design and Production Partner.

Welcome to Thompson Precision – Your Expert Mechanical Design and Production Partner.

Thompson Precision can offer a full design or design assistance service for mechanical and electro-mechanical projects. Our clients really value the ability to carry out the design, prototyping, pre-production manufacturing and in many cases final production, all under one roof and entirely in the UK. We have a great track record helping individuals with only an idea through to supporting OEM’s with specific mechanical engineering aspects of their products.

With a wealth of experience spanning over 80 years in precision engineering, we take pride in offering comprehensive design solutions for a wide range of projects. Whether you are an individual with a concept design or an OEM seeking specific mechanical engineering and machining knowledge, we have the expertise to cater to your needs.

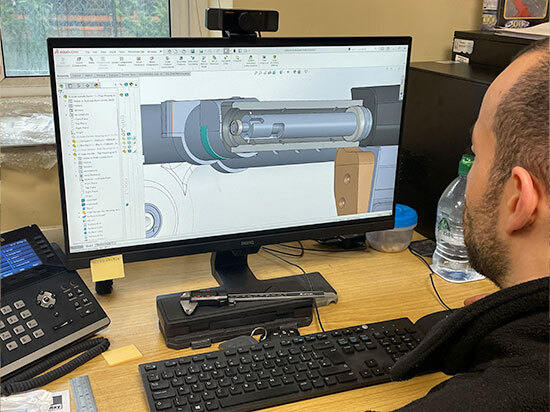

Cutting Edge Mechanical Design Technology

Our 3D CAD design service, powered by SolidWorks, has been honed and perfected over the past 20 years. We combine this cutting-edge technology with our in-house high precision CNC machining and assembly facilities, all conveniently housed within the same building. This ensures seamless collaboration and unparalleled efficiency for your projects.

Our 3D CAD design service, powered by SolidWorks, has been honed and perfected over the past 20 years. We combine this cutting-edge technology with our in-house high precision CNC machining and assembly facilities, all conveniently housed within the same building. This ensures seamless collaboration and unparalleled efficiency for your projects.

Mechanical and electromechanical design is where we truly excel. Our two full-time mechanical design engineers boast extensive experience and engineering acumen. We prioritise engineering practice alongside product design, always keeping an eye on the ultimate volume production process. This approach ensures that we provide cost-effective designs that can be efficiently manufactured by any producer, anywhere in the world.

With our industry-standard SolidWorks design package, the CAD files we provide are universally compatible, enabling smooth communication with manufacturers worldwide. Furthermore, our expertise in electromechanical design is complemented by the support of our sister company, JH May. Their rapid prototyping facilities play a crucial role in expediting the product development process.

Your One-Stop Service

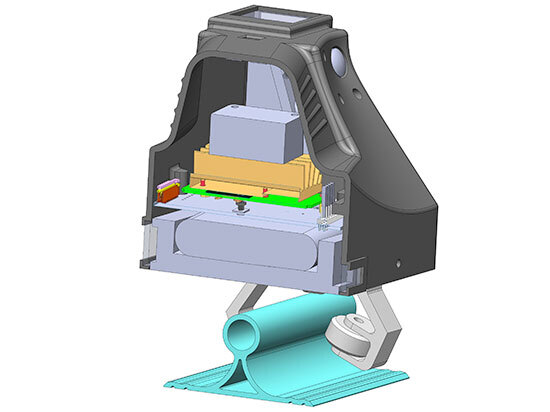

We pride ourselves on being a one-stop service provider. While Thompson Precision handles the electromechanical elements of your project, JH May excels in dealing with electronics enclosures, product outer panels, and a wide range of plastic and rubber parts.

We pride ourselves on being a one-stop service provider. While Thompson Precision handles the electromechanical elements of your project, JH May excels in dealing with electronics enclosures, product outer panels, and a wide range of plastic and rubber parts.

We are more than happy to undertake the 3D design work element alone, optimised for manufacturing elsewhere. However, most of our clients find immense value in utilising our comprehensive in-house machining, assembly, model making, and rapid prototyping services for both metals and plastics.

For a new project, our process begins with an initial design evaluation, followed by a cost estimation. Next, we present sketches and CAD visualisations, supported by 3D CAD models of key mechanical areas. With your approval, we proceed with product development, accompanied by a series of rapid prototype models in suitable materials for fit and function testing. Throughout this phase, we also work on the development of electrical and electronic elements. The final result is a fully functioning prototype, ready for testing and presentation to investors and potential customers.

For a new project, our process begins with an initial design evaluation, followed by a cost estimation. Next, we present sketches and CAD visualisations, supported by 3D CAD models of key mechanical areas. With your approval, we proceed with product development, accompanied by a series of rapid prototype models in suitable materials for fit and function testing. Throughout this phase, we also work on the development of electrical and electronic elements. The final result is a fully functioning prototype, ready for testing and presentation to investors and potential customers.

We take pride in our manufacturing facilities, which enable us to seamlessly undertake production. Who better to bring your product to life than the very designers who have been meticulously crafting it?

Discover the potential of Thompson Precision – Your reliable partner for all your mechanical design needs. Contact us now to explore how we can turn your ideas into reality.