Precision CNC Machining is a vital part of Precision Engineering. What is Precision Engineering you ask? It is the process of manufacturing products with very high accuracy and precision. This can be done through various methods, but one of the most popular ways to do it is through CNC Machining. In this blog post, we will discuss what Precision CNC Machining is, how it is used in Manufacturing, and some of the benefits that come along with using this technology!

What is CNC Machining?

CNC Machining is a manufacturing process that uses computers to control the movement of machines tools. This allows for very precise and accurate cuts to be made on metal or other materials. The CNC in CNC Machining stands for Computer Numerical Control. This means that the computer is telling the machine what to do, rather than a human operator.

CNC Machining is a manufacturing process that uses computers to control the movement of machines tools. This allows for very precise and accurate cuts to be made on metal or other materials. The CNC in CNC Machining stands for Computer Numerical Control. This means that the computer is telling the machine what to do, rather than a human operator.

This type of machining can be used for a variety of different applications, such as fabricating metal parts, cutting wood, or carving stone. It is most commonly used in the manufacturing industry to create products with high accuracy and precision.

How is Precision CNC Machining Used in Manufacturing?

There are many ways that Precision CNC Machining can be used in manufacturing. One of the most common ways involves using CNC machines to create very precise and accurate parts for products.

Another way that CNC Machining is used in manufacturing is through rapid prototyping. This is when manufacturers use CNC machines to create prototypes of products. This allows for companies to test out new ideas and designs before they go into full production.

CNC Machining is also used in the manufacturing of products for the medical industry. In this case, manufacturers often use CNC machines to create parts that are very precise and accurate. This is done in order to ensure that the products meet the high standards of quality that are required in the medical industry.

If you hadn’t gathered by now, the theme here is quality, precision and accuracy.

What are some of the Benefits of using CNC Machining Services?

There are many benefits to using CNC Machining in Manufacturing. Some of these benefits include:

There are many benefits to using CNC Machining in Manufacturing. Some of these benefits include:

– Increased Accuracy and Precision – When products are manufactured through CNC machining, they often have a much higher degree of accuracy and precision than those that are manufactured through traditional methods.

– Increased Efficiency – CNC Machining can often increase the efficiency of the manufacturing process, as it allows for parts to be created more quickly and with less waste.

– Reduced Costs – Precision Machining can also help to reduce the costs of manufacturing products. This is because it allows for parts to be made more quickly and with less waste.

– Increased Quality – Finally, CNC Precision Machining can also help to increase the quality of the products that are manufactured. This is due to the high degree of accuracy and precision that is often achieved through this process.

As you can see, CNC Precision Machining is a vital part of Precision Engineering. It can help to increase the accuracy and precision of products, as well as reduce costs and increase quality. If you are looking for a way to improve your manufacturing processes, then it is definitely worth considering using Precision CNC Machining!

Using Milling Machines in Precision CNC Machining

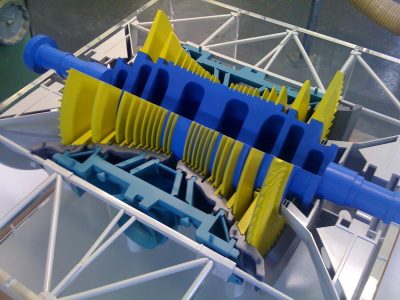

CNC milling is a type of CNC precision machining that uses a rotary cutter to remove material from a workpiece. This is done by moving the cutter around the workpiece in a controlled manner. The resulting shape is often cylindrical or conical.

CNC milling is used in a variety of industries, including automotive, aerospace, and medical. It is often used to create precision parts that need to meet very tight tolerances. In fact, CNC milling is one of the most common methods for machining high-precision parts.

Precision Engineered Components

Precision engineered components are essential in many different types of machinery. These components are used to ensure that the machinery functions correctly and with precision. In a manufacturing process there are often several different component parts that are critical to that businesses manufacturing processes, without which the production line would come to a stand still.

Without these precision machined components, the machinery would not be as effective or efficient. Some examples of machinery that use precision machined components include medical equipment, automobiles, and industrial machines. Precision machined components help to improve performance while reducing wear and tear on the machinery. When these components are used correctly, they can help to improve the lifespan of the machinery.

When selecting precision machined components, it is important to choose a supplier that has a good reputation and extensive experience in manufacturing these parts. The supplier should also have a comprehensive understanding of the specific needs of your industry and machinery. By working with a reputable supplier, you can be sure that you are getting high-quality components that will meet your needs.

Precision CNC Machining for High Volume Production

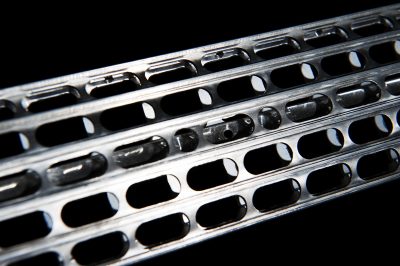

If you need to produce a large quantity of parts with high precision, then CNC machining is the ideal solution. CNC machines can create parts quickly and efficiently, making it possible to produce large quantities in a short amount of time. In addition, the accuracy and precision of CNC machining ensure that all the parts will be uniform and meet the required tolerances.

If you need to produce a large quantity of parts with high precision, then CNC machining is the ideal solution. CNC machines can create parts quickly and efficiently, making it possible to produce large quantities in a short amount of time. In addition, the accuracy and precision of CNC machining ensure that all the parts will be uniform and meet the required tolerances.

CNC Machining Services for Complex Parts

If you need to manufacture complex parts, then CNC machining is the ideal solution. With CNC and milling machines, it is possible to create parts with a wide variety of shapes and sizes. In addition, with accuracy and precision CNC machining you ensure that all the parts will be uniform and meet the required tolerances. This makes CNC and milling machining a great choice for manufacturing complex precision components and parts.

CNC Machining is Ideal for Manufacturing High-Precision Parts

If you need to manufacture high-precision parts, then CNC machining is the ideal solution. With CNC machines such as CNC milling machines, CNC turning, Cylindrical cutting tool machines and with the aid of computer aided design, it is possible to create parts with a wide variety of shapes and sizes. In addition, the accuracy and precision of CNC machining ensures that all the parts will be uniform and meet the required tolerances. This makes precision machining a great choice for manufacturing high-precision parts.