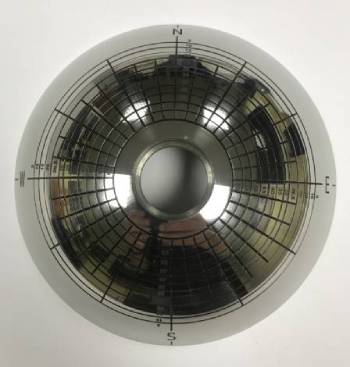

Instrument Housing 5 Axis CNC Machining – Aluminium

At Thompson Precision we regularly machine complex components for the Scientific Industry. Using 3 and 5 Axis Machining, we can machine a wide range of materials quickly, accurately and efficiently.

Specialising in fast-turnaround, low volume components, we offer a one-stop service allowing designers and R&D engineers to streamline their procurement – we can source material, machine the complex component and perform any additional processes you require including precision masking, conversion coatings, Hard and Sulphuric Anodising, Electroless Nickel plating, Gold Plating and more.

With over 20 CNC Machining Centres, we strive to always keep a machine free for fast-turnaround projects, and we regularly hold stock in a wide range of materials, allowing us to begin your project immediately. For more information on the materials we hold in stock, contact us today – we also work with suppliers around the world, allowing us to get common and non-standard materials delivered quickly.

We regularly machine aluminium, stainless steel, titanium, engineering plastics and many more materials, working with both standard and non-standard grades. We work closely with our suppliers to source the exact material you require.

Specialising in high-precision and low-volume parts, we often work with R&D departments in the prototyping of new products – our Fast Turnaround service means we can supply you with low-volume parts in a matter of days, and we’re regularly asked to machine different versions of the same component for testing purposes.

Our design team, using Solidworks software, can work with designers to ensure components are suitable for machining, and can often use their years of expertise to assist with solving difficult design problems.

With a dedicated Quality Management team, we can supply Co-Ordinate Measuring and First Article Inspection Reports to ensure your components are machined to the highest accuracy, and full traceability of materials if required.

Enclosures CNC Milled from Solid Billet

We often machine large, bespoke enclosures milled from solid billets of material – these can be used to securely house complex electronics or scientific equipment in difficult environments. Bespoke enclosures can be made from a wide variety of materials and can include complex machined features like heatsinks and precision machined access and fixing points. If you are an OEM supplier who needs a bespoke solution, contact us today to see how we can help.

Bespoke Breadboards and Special Fixtures

Precision Rain Guage 5 Axis CNC – 316 Stainless

We can design and manufacture bespoke fixtures, tooling, clamping jigs and aluminium breadboards to support scientific projects when an off-the-shelf option is not suitable. High precision, attention to detail and high-speed service when needed are all guaranteed. We specialise in projects with a high level of difficulty and complexity utilising the latest 5 axis CNC machining plus metal and plastic 3D printing technology.

For more information on how we can assist you with your next project using 3 and 5 Axis CNC Machining, talk to us today on 01277 365500 or email [email protected].