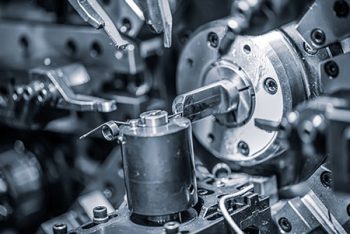

Precision engineering is used in many spheres of industry and manufacturing in order to create items which are highly detailed, intricate, and yet need to be repeated multiple times.

Precision engineering is also used in a range of high-technology fields, including software engineering, optical engineering, aviation and electrical engineering, and electronics including IT.

These fields require a large number of very small items to be made for each piece, every one completely identical to the next.

What is Precision Engineering Used for?

Precision engineering is designed to create items which are too intricate for manual engineering. The devices used in precision engineering have very precise movements, much smaller than could be managed by manual systems. They are also valuable in reducing the basic costs of manufacturing, as they can reproduce the same item without mistakes, and without having a number of discards due to flaws in the process. The precise nature of the manufacturing process means that objects both large and small can be made using the rules and systems devised by engineering system.

One of the most regular uses of precision engineering is to construct dynamic models of a design in order to test whether it will work. By being able to approach the design in a systematic manner, engineers can calculate whether there are errors in the proportions laid out in the design, or whether there are any problems with the existing dimensions. By testing it out using this technology, the practicality of a design can be tested and any flaws removed before the design is finalised, helping to eliminate later problems. This is essential in many forms of engineering and electronics, where small flaws could cause problems with the entire system.