At Thompson Precision Engineering (the trading name of EH Thompson) we think of ourselves as industrial problem solvers rather than simply an engineering business. From our early days before and during World War II to now, we have always striven to accomplish the seemingly impossible.

At Thompson Precision Engineering (the trading name of EH Thompson) we think of ourselves as industrial problem solvers rather than simply an engineering business. From our early days before and during World War II to now, we have always striven to accomplish the seemingly impossible.

A History of Problem Solving

EH Thompson was founded in 1939 as a specialist scientific instrument maker taking on sub-contract work. Even in these early days we began specialising in projects involving the design, machining and finishing of a variety of components and assemblies that were considered too difficult or even impossible by others in the industry.

These problem solving abilities proved fortunate as shortly after commencing business World War II began and EH Thompson had to switch from manufacturing scientific instruments to making ammunition, weapons and defence hardware instead. And once the war ended production had to switch once more, with the company then becoming a leading supplier to Ford Motor Company. We continued to focus on automotive and subsequently high pressure hydraulic systems until the 1980s.

EH Thompson Now

Focus then switched to the manufacture of high precision aerospace components and the company began sub-contracting some of the work to JH May, who specialised in pattern making and prototyping. EH Thompson eventually acquired JH May in 2003, combining the strengths of both companies.

Focus then switched to the manufacture of high precision aerospace components and the company began sub-contracting some of the work to JH May, who specialised in pattern making and prototyping. EH Thompson eventually acquired JH May in 2003, combining the strengths of both companies.

As Simon Terry (Managing Director at EH Thompson) says, “The resulting business combines the best of high precision engineering and bespoke project manufacturing with an enthusiastic and entrepreneurial spirit that allows us to work with larger companies and bypass the issues that they have in terms of getting things done quickly. Many of our customers rely on us to confirm that their design concepts are feasible to manufacture. As a result we get most of our enquiries from design offices rather than procurement and this develops into trusted relationships that go in both directions.”

One recent modern day project that showcases our creativity and adaptability is a commission to build a life size reproduction of the Lockheed 5B Vega flown across the Atlantic and then non-stop across the US by Amelia Earhart in 1932. Made from wood, fibre glass and aluminium, the replica was designed to be hung on display an impressive thirty feet above the ground.

Collaborating with WNT

However it is another project involving the machining of a series of architectural elements that really highlights our engineering skill and experience with custom projects. This was very much an engineering based project and was challenging not only because of the detailed and complex cutter paths but also because the parts were to be machined from solid 316 stainless steel billets. The largest of these weighed around three tonnes, with only half a tonne of material left after machining, so the large amounts of steel being removed posed a unique challenge. This combined with the high value of the parts to be machined required a review of milling strategies and so we turned to WNT, supplier of high quality metal cutting products to the machining industry.

However it is another project involving the machining of a series of architectural elements that really highlights our engineering skill and experience with custom projects. This was very much an engineering based project and was challenging not only because of the detailed and complex cutter paths but also because the parts were to be machined from solid 316 stainless steel billets. The largest of these weighed around three tonnes, with only half a tonne of material left after machining, so the large amounts of steel being removed posed a unique challenge. This combined with the high value of the parts to be machined required a review of milling strategies and so we turned to WNT, supplier of high quality metal cutting products to the machining industry.

As our Production Manager, Ian Cain, put it, “The roughing cycle for the largest piece involves many 100’s of hours cutting and on top of that we have a series of single finishing cycles each of 100 plus hours to contend with. This means we need confidence in the cutters to be able to operate lights out.”

In addition to this, tool extensions were needed to machine such large billets. The button-style cutters needed a gauge length of 250mm for rough machining and this needed to be extending to 350mm for finishing, but reliability and consistency were still paramount.

Machining Strategy

We worked with Adam Cross, WNT’s Technical Sales Engineer, to come up with a machining strategy using sister tooling that would permit us to leave the machine running without the need to keep an eye on it. The length of the roughing and finishing cycles meant that the machine had to run for long periods at a time and couldn’t therefore be manned all the time, not normal practice with a material like 316 stainless steel. Consistent tool life was therefore one of the most important parts of this project. With Adam and WNT’s help, we managed to achieve this while still maintaining very competitive performance for such a testing application.

We worked with Adam Cross, WNT’s Technical Sales Engineer, to come up with a machining strategy using sister tooling that would permit us to leave the machine running without the need to keep an eye on it. The length of the roughing and finishing cycles meant that the machine had to run for long periods at a time and couldn’t therefore be manned all the time, not normal practice with a material like 316 stainless steel. Consistent tool life was therefore one of the most important parts of this project. With Adam and WNT’s help, we managed to achieve this while still maintaining very competitive performance for such a testing application.

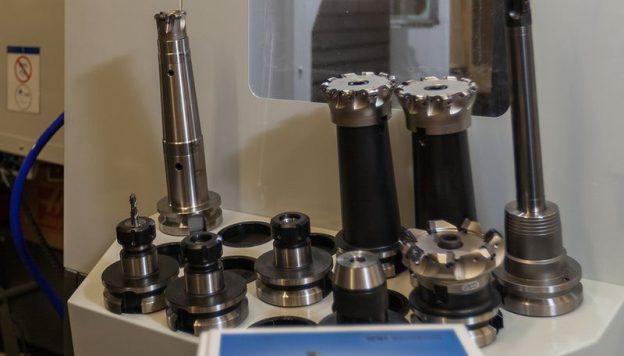

WNT chose its Dragonskin HCN 5235 grade of indexable inserts for both the roughing and finishing. This is able to significantly reduce cycle times on stainless steel and heat resistant alloys, and as well as machining times being cut by up to 40%, tool life was increased by 50% in some cases.

“With cycle time being less of a priority we focussed on getting tool life to a point that we were happy with. That said, using the WNT System 2510 RS 100 mm diameter button cutters with RPHX 1204M8EN-M31 HCN 5235 inserts we achieved cutting data of 186 m/min with a feed/tooth of 0.35mm,” said WNT’s Adam Cross. “To assist with the tool life we also ran the cutters dry, as applying coolant would have introduced an element of thermal shocking that would have reduced the life of the inserts.”

A WNT System K 2000 32 mm copy milling cutter was used with ROHX 3250 R16-FM3 WAN2210 inserts for the finishing operation. The cutters’ tool life on the finishing cuts was impressive, running at 200m/min surface speed and 0.15mm/tooth feed rate.

A mixture of BT40/50 and HSK tool assemblies were used to suit the variety of spindles we have available at EH Thompson. As the surface finish of the final product was so vital, the final machining operation quality had to be outstanding and tools had to be set up incredibly accurately to avoid any mismatch when sister tooling was called up. WNT’s support was invaluable in this regard.

As Simon Terry says, “This project is typical of what we achieve on a regular basis here at Thompson Precision Engineering. The partnership with WNT ensures that we achieve the machining criteria needed to deliver the parts to specification, alongside our policy to invest in the best tooling, software and plant for the job. In this case we purchased a brand new EC1600 horizontal machining centre from Haas in order to ensure we had the machining capacity. Much of our business now comes from existing customers and word of mouth. We have a reputation as innovative engineers who can apply our knowledge to solve complex problems. We are repaid by winning exciting and interesting engineering conundrums such as this.”

As Simon Terry says, “This project is typical of what we achieve on a regular basis here at Thompson Precision Engineering. The partnership with WNT ensures that we achieve the machining criteria needed to deliver the parts to specification, alongside our policy to invest in the best tooling, software and plant for the job. In this case we purchased a brand new EC1600 horizontal machining centre from Haas in order to ensure we had the machining capacity. Much of our business now comes from existing customers and word of mouth. We have a reputation as innovative engineers who can apply our knowledge to solve complex problems. We are repaid by winning exciting and interesting engineering conundrums such as this.”

With thanks to WNT for allowing us to use information and photos taken from their news post: Problem Solved at EH Thompson – With Help From WNT