The name “CNC” actually stands for Computer Numerical Control. CNC Machining is a process which involves the use of computers to control machine tools.

The first NC machines (Numerical Control) were developed in the 1940s and modernised throughout the 1950s. These pioneering machines were based around existing tools which were modified with motors. The motors moved controls to follow points fed into the system on punched tape. Punched tape is a paper tape which was perforated according to a code to convey instructions or data to a data processor. Punched tape technology is now obsolete but can often be seen in museums.

Punched tape technology was replaced by analogue computer processing and in the present, we now use digital computer processing.

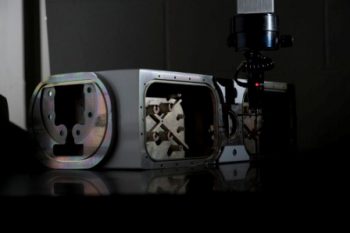

On the surface, the computer used alongside a CNC machine may look like a normal PC, but the computer’s unique software and control console makes it an impressive workhorse. The computer is not there to control the machine but to instruct it on the design by way of computer software.

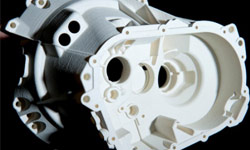

CNC machining is widely used for intricate work. The CNC system is far more precise than the human counterpart. On reproduced items the CNC system is able to produce perfect replicas every time. Each item will be exactly the same, with no flaws or problems in the design. CNC systems are also used for constructing complicated 3D shapes and designs, for example in artwork or in aeronautics.

CNC machining language is often referred to as a G-code.

There are five different types of CNC machines:

- CNC Plasma Cutting Machine

- CNC Laser Cutting Machine

- CNC Milling Machine

- CNC Router Machine

- CNC Lathe Machine

Does CAD Drawing still have a role in the CNC world?

CAD drawing still plays a significant role in the progress. Firstly a CAD drawing is created (either 2D or 3D). Once the drawing has been approved, a code is created that the CNC machine will follow and understand. The program is then loaded onto the computer and finally an operator will run a test on the program to ensure there are no problems. This process is known as “cutting air”. Cutting air is a very important step in the process as any mistakes with speed and tool position can be rectified before production commences.

Advantages

There are many advantages to using CNC Machining. The process is:

- More precise

- Easier to produce identical repeated designs

- Able to produce complex shapes (including 3D that would be almost impossible to achieve with manual machining)

- Able to provide exact positioning and velocity

- Able to achieve higher levels of precision to a human counterpart

Why does Thompson Precision Engineers use CNC Machining?

Thompson Precision Engineers have been established since 1939 and have maintained the tradition of producing high precision components and assemblies. As with any organisation we have sought to utilise the most up to date technology and have embraced its characteristics. We have been using the CNC Machining programme for over 10 years have a solid understanding of the programme and how it improves quality within the industry, we whole heartedly believe CNC machining saves time and resources from prototype to production.

Thompson Precision Engineers have been established since 1939 and have maintained the tradition of producing high precision components and assemblies. As with any organisation we have sought to utilise the most up to date technology and have embraced its characteristics. We have been using the CNC Machining programme for over 10 years have a solid understanding of the programme and how it improves quality within the industry, we whole heartedly believe CNC machining saves time and resources from prototype to production.