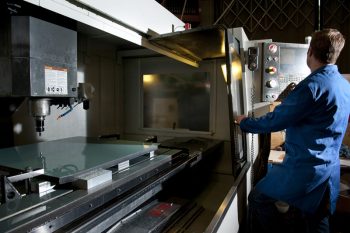

The basic idea of milling is to remove material from a larger piece, whether wood, metal, plastic or something else. Low volume milling refers to the case where only a small number of units are milled compared to regular manufacturing processes in which thousands or millions of pieces of materials are milled to the desired specification. Finally, the “CNC” part refers to the fact that the milling is directed by computer, not by hand. CNC stands for Computer Numerical Control and is the name given to the process by which a computer translates digital information from a computer into milling instructions in equipment capable of removing material.

Low Volume CNC milling is, therefore, the combination of all of the above concepts: where a computer directs the milling of a small number of units.

The Benefits Of Low Volume CNC Milling

Low volume CNC milling has many benefits over and above standard milling processes which can help you and your business develop the products that you want.

- Easing The Transition From Prototype To Full-Scale Production. Let’s say that you’ve created a prototype that you’re happy with but don’t yet want to commit to full-scale production because you don’t have data on real-world performance. Low volume CNC milling can provide a supply of parts that you need to build your product, giving you an intermediate stage between prototype and high-volume manufacturing.

- Gain Added Flexibility. Once you’ve committed to high-volume production, it’s hard to make changes to your product. But with low volume CNC milling, you can alter the specifications of each batch as you update your design.

- Save Money. Low volume CNC milling requires a much smaller financial outlay than traditional high volume operations. It, therefore, enables businesses to save money while working towards scale.

- Launch Products Faster. It can take a long time to set up full-scale manufacturing facilities. Utilising low volume CNC milling can help you bring products to market sooner by removing bottlenecks in your production process.

How Thompson Can Help With Your Project

Here at Thompson, we have substantial experience with low volume CNC milling, offering a flexible service that you can use to assist your production process and get your product off the drawing board and into the hands of customers.

CNC milling, as a subtractive manufacturing technique, is ideal for all kinds of operations that you may need to perform. Not only can Thompson help you make individual components, but you can also take advantage of our low volume CNC milling services to create moulds and frames to produce more products in the future.

With Thompson, you get many benefits. To start, you can order and test many different design specifications. Not happy with the way that your product is currently performing? Then come back to us, use our CNC milling technology, and get something new that performs better.

To get started is easy. Just sent us your CAD designs and we can input them into the computer and begin creating your design at low volume immediately. It couldn’t be easier.