Plastic CNC machining is a process that uses computer-aided design (CAD) and computer-aided manufacturing (CAM) to create 3D objects from plastic material.

This plastic machining process can be used for a variety of purposes, including prototyping, product development, and manufacturing. In this blog post, we will discuss the benefits and different applications of plastic CNC machining.

Benefits of using plastic CNC machining

Plastic CNC machining is a process that uses computer controlled tools to cut and shape plastic parts and it has several benefits:

- Speed: The process is quick and efficient

- Tight tolerances: A CNC machine can produce plastic components with very minimal variation.

- Complex shapes: In addition, CNC machining can be used to create complex shapes that would be difficult or impossible to produce using other methods. In CNC machining, a computer controls the movement of cutting tools, making it possible to produce parts with high levels of precision and accuracy.

- Cost effective for small batches: A CNC machine is often used to create plastic prototype production runs at low volume, as it is relatively quick and easy to set up and so more cost effective than traditional machining methods.

- Accuracy and repeatability: The process can also be used to produce large quantities of identical parts because of its accuracy, so it is also useful for mass production of complex parts.

A CNC machine is a versatile and powerful tool that can be used to create a wide variety of plastic components.

Using Different Types of Plastics

A variety of different types of plastic materials can be used in CNC machining, depending on the application. Here are just a few examples:

Nylon

When it comes to CNC plastic machining, nylon is a popular choice. Nylon is strong and durable, yet lightweight and easy to work with.

It also has a high melting point, making it ideal for use in high temperature applications. In addition, nylon is resistant to abrasion and chemicals, so it won’t break down easily over time.

As a result, parts made from nylon are often more reliable and longer-lasting than those made from other materials. Nylon is also an excellent electrical insulator, making it ideal for use in electronic components.

PTFE

PTFE, or polytetrafluoroethylene, is a type of plastic that is known for being strong and durable. It is often used in applications where high temperatures are a concern, as it has a high melting point.

PTFE is also very resistant to chemical attack, making it a popular choice for use in chemical processing plants.

In addition, PTFE is non-stick, making it an ideal material for use in cookware and other applications where sticking and build-up are a concern.

When it comes to plastic CNC machining, PTFE is often used to create parts that will be exposed to high temperatures or corrosive chemicals. The non-stick properties of PTFE make it ideal for use in applications where lubrication is not possible or desirable.

PTFE is a versatile material that can be used in a wide variety of applications that require strength, durability, and resistance to high temperatures or corrosive chemicals.

Acetal

Acetal is a strong, lightweight plastic that is often used in CNC machining. It is easy to machine and has a low coefficient of friction, making it ideal for applications where high precision and smooth operation are required.

Acetal has excellent wear resistance and chemical resistance, making it a good choice for parts that will be exposed to harsh conditions.

It can also be easily joined using adhesive or welding, which makes it possible to create complex shapes and designs.

PET

Polyethylene terephthalate, or PET, is a type of plastic that is widely used in food and beverage packaging as well as in the manufacturing of medical devices and electronics.

PET is an ideal material for CNC machining due to its high strength and stiffness, as well as its resistance to impact and wear.

It can be easily machined to very tight tolerances, making it an ideal choice for applications where precision is critical.

While PET is not the cheapest option for CNC machining, its superior properties make it an excellent choice for many applications.

PEEK

Polyetheretherketone, or PEEK, is a semi-crystalline thermoplastic that offers a unique combination of properties, including excellent mechanical and chemical resistance.

It is strong and stiff, with a high melting point and is resistant to heat, chemicals, and wear. For these reasons, PEEK is often used in aerospace and medical applications.

PEEK is well suited to plastic CNC machining and can be machined using CNC technology to create precise parts with very minimal variation as it has a low coefficient of friction and high wear resistance.

It can also be machined at high speeds and does not produce harmful fumes during processing.

When machining PEEK, it is important to use high speed tools and coolant, as the material can produce a lot of heat when cut. In addition, machinists must take care to avoid chips and burrs, as these can cause the material to degrade over time.

With the proper precautions, however, PEEK can be an excellent choice for plastic CNC machining.

Applications for Plastic CNC Machining

Some of the most common applications for CNC machining include creating medical devices, automotive parts, aerospace components, and consumer electronics, though there are plenty of other applications in the manufacturing industry too.

Medical devices

When it comes to medical devices, precision is key. That’s why many manufacturers are turning to CNC plastic machining for the production of everything from prosthetic limbs to artificial hearts.

When it comes to medical devices, precision is key. That’s why many manufacturers are turning to CNC plastic machining for the production of everything from prosthetic limbs to artificial hearts.

CNC plastic machining allows for a high degree of accuracy and repeatability, which is essential for medical devices that must meet stringent safety standards.

In addition, it offers a number of other benefits, including a wide range of material options and the ability to produce complex shapes.

This process is quickly becoming the go to manufacturing method for medical device manufacturers.

Automotive components

Designers and engineers are increasingly turning to CNC machines for the development of automotive components.

Plastic offers a number of advantages over traditional materials such as metal and wood.

It is lighter in weight, which can lead to reduced fuel consumption. It is also more resistant to corrosion and wear, making it ideal for parts that will be exposed to harsh conditions. And it can be moulded into complex shapes that would be difficult or impossible to create using other methods.

Plastic CNC milling is becoming an increasingly popular choice for the development of automotive components.

Aerospace components

Aerospace engineering is an advanced field that designs, tests, and builds aircraft, missiles, satellites, and spacecraft. The components of these machines must be able to withstand extreme conditions, such as high temperatures and pressures.

As a result, aerospace engineers often turn to CNC machines to create precision parts.

This process is well suited for creating complex shapes and fine details. And plastic is an ideal material for aerospace parts because it is strong yet lightweight and can withstand harsh chemicals and high temperatures.

For these reasons, CNC machined plastic parts are often used in aircraft brakes, fuel lines and nose cones.

Consumer electronics

CNC machines are a popular choice for consumer electronics. This is because they offer a number of benefits over other manufacturing methods, such as high precision and repeatability.

A CNC machine can also be used to create complex shapes that would be difficult or impossible to create using other methods.

Because of this, plastic CNC machining is often used for parts such as housing enclosures, LCD screens, and keypads.

CNC Machining for Your Business

If you are considering using plastic CNC machining for your business, contact a reputable company that specialises in this process and is able to help you determine if it is the right solution for your needs.

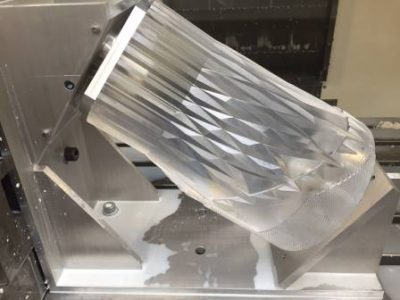

At Thompson Precision, we have a wide variety of CNC machines that allow us to machine plastic materials into complex shapes with very minimal variation.

We work with a variety of industries throughout the UK, and we are able to tailor our services to meet the specific needs of our customers.

Our CNC milling machines and lathes are some of the most advanced in the world, and they allow us to create nearly any shape or design that our customers require.

In addition, our team of highly skilled engineers and technicians have extensive experience working with plastic material, and they are able to provide expert advice and guidance throughout the machining process.

As a result, we are able to provide our customers with the highest quality products and services available.

Contact us today to find out how we can help with your plastic prototype and other plastic CNC machining requirements.