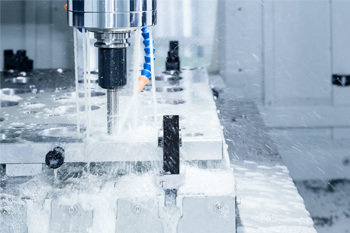

Precision CNC Machining involves the removal of excess raw materials with immense accuracy with the aim of creating a finished product. It’s shaping something into a specific end result, it could be a component part, a finished product, prototype or piece of art. It’s something that impacts all of us, most without even realising.

It sounds simple right? Well, it’s really not as straightforward as it sounds, the process can involve a number of steps including initial drawings, milling, turning, cutting a variety of different materials. Usually aided by computers that are able to make incredibly precise movements.

What is Precision CNC Machining Used for?

Most objects we use in every day life will have been machined in some way, at home it could be a small component part of an everyday appliance or a larger object. In the workplace even the machines used in a factory, tools, aircraft and car parts, in fact pretty much every industry will have been affected in some way.

Technology has shaped the way that Precision CNC Machining is done, with computer programming and more advanced CNC equipment available the achievable results are pretty amazing. Even old parts where the manufacture was by hand can be replicated exactly as they once were, this is especially important when producing a replacement part where it is currently obsolete. If the part that were produced by Precision CNC Machining were too perfect, it likely wouldn’t function properly, or if it did, it could damage other neighbouring parts. Sounds strange right? Producing a non-perfect part on purpose.

Once a product is ready to be made, high volume projects can be completed.

The Role of CAD (Computer Aided Design)

CAD allows the machines to be programmed so that they create the right end result to the right specifications. Using drawings supplied by the client or producing them from scratch a CNC engineer can use computer aided design to create highly accurate 3D drawings. This stage is vital as if any mistakes are made, the end result might not be what the clients want.

Using computers and new technology is all well and good, but this doesn’t replace experience and manual skill in its entirety. Using a combination of human knowledge and computer technology can help achieve amazing results.

Once the drawings are completed it’s important to understand which materials will work best for the final product. This will depend on the kind of product, it’s application and the environment in which it will be used. Precision CNC Engineers will use their experience and alongside discussion with the client will make suggestions about the best materials to use for each individual project.